Production & Distribution

Providing Peace of Mind and Safety

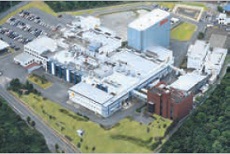

In keeping with this spirit, Zeria has built an optimal production structure underpinned by the Saitama Plant, the Tsukuba Plant, 2nc Tsukuba Plant, IONA’s Fukushima Plant, Tillotts Pharma’s Ziefen Plant, ZPD’s Esbjerg Plant and F.T. Pharma’s Cat Lai Plant. Through this framework, Zeria makes its utmost efforts to manufacture high quality and highly reliable products.

The Saitama Plant produces a variety of ethical pharmaceuticals and OTC drug products as the center of Zeria’s production facilities. The Tsukuba Plant, which produces a range of products classified as OTC drugs, designated quasi-drugs, health foods and drinks, features a fully automated manufacturing line encompassing all processes from the placement of empty containers to packaging.

Both plants have obtained certification for ISO 14001, the international standard for environmental management systems, and are undertaking environmentally conscious production activities. The distribution of pharmaceuticals requires a variety of response capabilities that include the distribution management ability to handle largemix small-quantity production, make immediate delivery and reduce inventory volumes. To respond to the specialized requirements of drug distribution, Zeria aims to reduce distribution costs and realize

fast and accurate delivery. These efforts are focused on our targets of achieving “365-day operation and shipment,” “shortening lead time,” “reducing wasteful costs” and “improving distribution quality.”

Production Bases

Saitama Plant

[Main production lines]

Pharmaceutical products and OTC drugs(oral solid dosages, ophthalmic solutions, ointments, injections, etc.)

Tsukuba Plant

[Main production lines]

Pharmaceutical products, designated quasi-drugs and health foods (drinks (lightly carbonated and non-carbonated), tablets, granules, etc.)

2nd Tsukuba Plant

[Main production lines]

Pharmaceutical products, health foods and liverhydrolysate.

IONA’s Fukushima Plant

[Main production lines]

Cosmetics and quasi-drug products, etc.

Tillotts Pharma’s Ziefen Plant (Switzerland)

[Main production lines]

Pharmaceutical products (oral solid dosages, etc.)

F.T. Pharma’s Cat Lai Plant (Vietnam)

[Main production lines]

Pharmaceutical products and OTC drugs (oral solid dosages, ophthalmic solutions, injections etc.) and health foods, etc.